New generations of thigh panels and driver head surrounds for ovals will be incorporated in the Dallara chassis for the 2015 Verizon IndyCar Series season, and INDYCAR continues to evaluate additional updates with driver safety the main priority.

The fourth-generation chassis enters its fourth year of competition on the most diverse set of racetracks in motorsports with a twist. Aerodynamic bodywork kits supplied by manufacturers Chevrolet and Honda will debut in the Firestone Grand Prix of St. Petersburg on March 27-29.

A modification of the headrest surround for road and street courses to reduce the low G force levels usually seen on bumpy street circuits when the driver’s helmet buffets the headrest was introduced for 2014. Similar construction, utilizing three different density layers of Confor foam, will be utilized for the oval headrest surround.

Click it: Review of engine regulations and future || Review of aero kits

“With the help of Dallara, we found a rubberized material to replace the Kevlar covering for the oval spec headrest,” said Jeff Horton, INDYCAR’s director of engineering/safety. “As the Kevlar gets painted and repaired from cracks, it gets harder and doesn’t work as well. The rubberized covering stays flexible and supports Velcro, so the extra headrest pads that drivers like to use will come off easily.”

The road/street course headrest has a Nomex covering, and Horton said either that material or the rubberized cover can be used on road/street courses. Both headrests use Expanded Polypropylene (EPP), an engineered plastic foam material also used in molding driver seats, behind the driver’s head.

Not so rigid thigh panels introduced

Interior panels of EPP sandwiched by carbon fiber on both sides of the cockpit will provide additional protection to the driver’s thighs and pelvis.

“The design allows more support at low lateral Gs, but in an accident situation allows it to collapse to give the drivers some compliance side to side,” said Horton, noting that the new Indy Lights Presented by Cooper Tires car was designed with this update.

Pockets for anti-roll bar adjuster handles, located just behind the dashboard bulkhead, have been incorporated in both panels. Previously, both anti-roll bar adjusters were on the driver’s left side.

“What that did was put a hard point right where the driver’s leg is,” Horton said. “For this year we’ve split the roll bar handles. The left controls the rear and the forward control will be on the right.”

For 2014, carbon fiber panels were bonded to the exterior and interior sides of the cockpit supplement the Xylon anti-intrusion panels introduced in 2008 to increase the chassis’ side impact integrity. Additionally, a carbon fiber reinforcement ring was added to increase the structural integrity of the cockpit opening.

Hole in the floor

A modified chassis undertray will be incorporated for all events this season as a companion to aero kits to dramatically reduce the incidence of the car becoming airborne in accident situations.

Surface area was reduced by cutting out triangle-shaped sections on either side of the cockpit. The modification has been vetted through high-speed, on-track testing.

Steering damper testing continues

Testing of a hydraulic system to reduce the travel rate of the steering wheel in an accident situation progressed in 2014 from drivers providing feedback from on-track, non-accident situations of prototypes to crash testing.

This week, Horton and INDYCAR medical consultant Dr. Terry Trammell put the latest iteration of the system to crash sled testing at the Center for Advanced Product Evaluation in Westfield, Ind.

A study conducted by Trammell concluded that because of the violent rotation of the steering wheel – most often in accident situations on road and street courses – injuries occur when either the hand comes off the wheel and is hit by one of the knobs on the wheel or when a finger/thumb gets caught in the steering wheel and is rotated too far.

“One of the potential solutions we’ve looked at is a steering damper, which basically is a shock mounted on the steering rack and pinion setup so any shock or excessive movement by the tire, which is transmitted through the track rod into the steering rack with the pinion ratio, makes the steering wheel move at an extremely high rate,” Horton said.

“It’s a difficult project because there are a lot of forces involved that have to be slowed down and diminished very quickly. Our target is to limit the rotation in the first 50 to 150 milliseconds to 90 degrees or less. That is a range in which a driver’s hands normally move, which shouldn’t put them out of position enough to cause an injury. In our study, 2,000 degrees per second relates to 6 or 7 inch per second on the rack.”

A proven system could be implemented toward the end of the season.

Potential fin for debris deflection

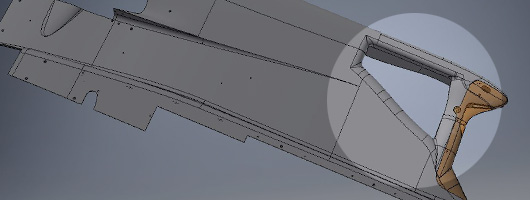

A carbon fiber fin attached to the chassis forward of the cockpit is being evaluated as a potential deflector of track debris, according the INDYCAR technical director Kevin Blanch.

A carbon fiber fin attached to the chassis forward of the cockpit is being evaluated as a potential deflector of track debris, according the INDYCAR technical director Kevin Blanch.

Verizon IndyCar Series drivers have provided feedback on line of sight with multiple iterations – one and side-by-side fins – in the Dallara simulator and on the Indianapolis Motor Speedway oval this fall.

“We’ll get additional feedback in testing as we develop,” Blanch said. “It could be an option in the future to hopefully redirect debris.”

Examination of potential solutions has been ongoing since May when James Hinchcliffe was struck in the helmet by a piece of debris during the Grand Prix of Indianapolis. Some drivers, such as Josef Newgarden, Helio Castroneves (left) and Simon Pagenaud, use short wind screens, but they aren't intended to deflect debris.